Drive Productivity to Create Value for Your Customers

We help business-to-business (B2B) suppliers create value for their customers (and their customer’s customers) while capturing more value for themselves—which raises the question, how does a supplier’s offer help in a manner that is profitable for themselves, their channel partners, and end customers? One approach involves helping one or more of these players improve productivity. The goal is either to increase output with labor and capital remaining constant, or to reduce labor and/or capital for the same level of output. The manufacturing industry, for example, has experienced a significant revolution in productivity in the last 50 years and increased productivity by about six-fold in that time period. However, not all industries have experienced that same productivity improvement. Over that same period, the construction industry’s productivity remained flat[1] [see Figure 1].

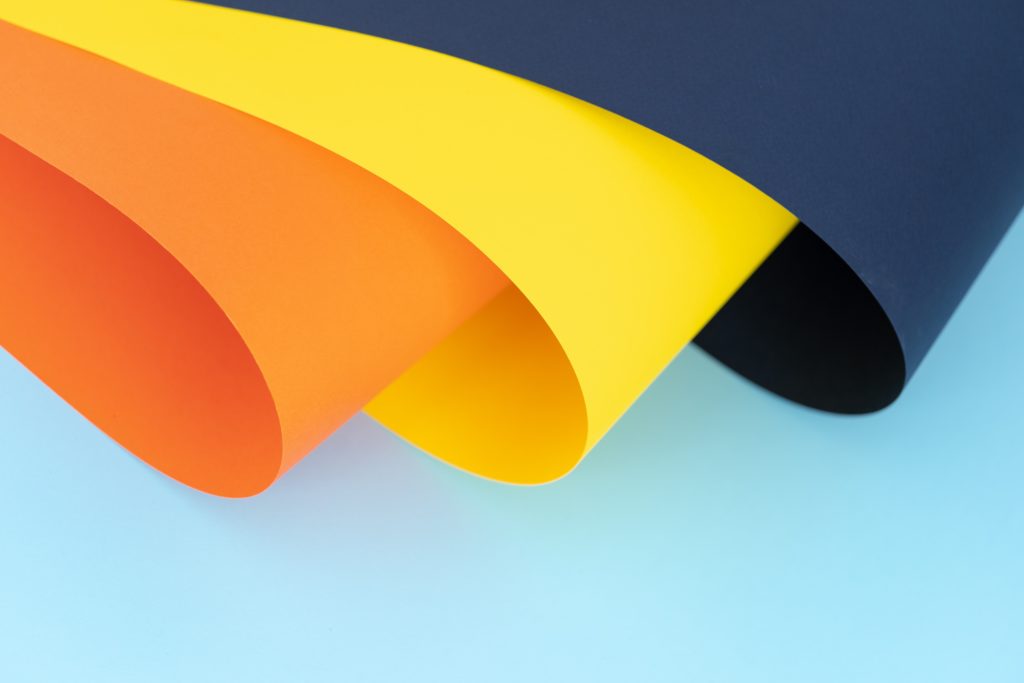

Figure 1:

Figure 1. Graph of the Manufacturing and Construction Industries

Productivity Index (1964-2014). Retrieved from http://www.bea.gov/.

Using examples from innovators who combatted poor productivity, we will map out three strategies suppliers can apply in order to tackle this challenge and position themselves as a leader for improving productivity.

First, be your customers’ sponsor to help them sell value and productivity to their customers. Help identify and support their initiatives by sharing your own experiences and expertise. For example, a distributor of door hardware wants to position itself as more than a “drop-and-ship” warehouse to its customers: general contractors. The distributor believes it can add value and improve productivity by pre-installing the locks and accessories on the doors in-shop, so that it saves labor and clutter on the contractor’s job-site. The distributor’s supplier, the door hardware manufacturer, can take it one-step further by helping to package the doors and hardware differently to make pre-installation more effective, and even share manufacturing best practices for re-packaging the pre-installed doors. By acting as a sponsor, the supplier enables itself and the distributor to defend premium prices for their added value, and the contractor saves on expensive labor costs.

Second, take the lead on improving productivity by simplifying information flow processes, which includes ordering, responding to requests for information, quoting, and problem solving processes. Evaluate how effectively information flows between players during these processes to enable decision-making or key actions. Do any of these processes require iteration or time-consuming steps? By taking the time to map out these processes and identify common areas for error or unnecessary delays, a supplier can improve productivity. For example, in agriculture equipment manufacturing, suppliers such as John Deere have enabled precision farming with robust information collecting and sharing mechanisms between the operator, dealer, and OEM. Dealers can retrieve diagnostic codes remotely, which saves valuable time.[2] Focusing on simplifying complex information flow processes can enable faster decision-making and problem solving, and thus improve productivity.

Lastly, be the collaboration coordinator. In complex B2B markets, many players need to work together to accomplish routine tasks, such as setting specifications, or major strategic tasks, such as innovating on a new tool or process. If the supplier can position itself as the collaboration coordinator and bring all the necessary players to the table to make efficient decisions and plans, it can drive productivity while also promoting its own power with upstream and downstream players. For example, a food and beverage packaging manufacturer wanted to help a quick-serve restaurant customer better utilize its new rapid cook ovens. By bringing together the oven manufacturers, ingredient/food suppliers, and the restaurant chain, the packaging supplier was able to drive new packaging innovations for this type of oven that reduced labor while maintaining high levels of food quality.[3] Whenever a supplier can take on that collaboration coordinator role, it can provide advantages not only for itself, but also to the entire process to improve productivity.

When suppliers can improve productivity for their partners and/or end customers, they can expect to capture a portion of that value for themselves through increased price or share. In order to diagnose where to start, a supplier should map out its entire customer chain to understand how its product flows to the end customer. Which players perform which value-add activities, and where are there gaps and inefficiencies? The three strategies outlined here offer proven mechanisms for addressing those inefficiencies and positioning a supplier as a leader in improving productivity.

[1] U.S. Bureau of Economic Analysis. Graph of the Manufacturing and Construction Industry Productivity Index (1964-2014). Retrieved from http://www.bea.gov/.

[2] Retrieved from https://www.deere.com/.

[3] Leichum, Axel J. & Putnam, Laura J. (2016). Remaining Innovative in a Disrupted Ecosystem. Presentation, SAMA’s 2016 Annual Conference.